Products

DH series high-efficiency dryer

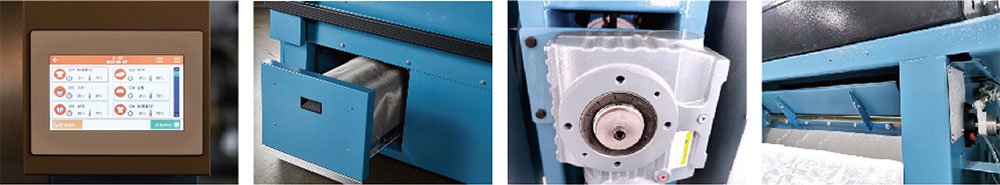

Touch screen operation panel.

Store up to 999 programs.

Temperature difference “power cut-off”.

Freely select able cooling temperature and time.

Anti-wrinkle function.

Manually start cylinder reversal for easy unloading.

Large basket opening, more ergonomic, convenient loading and unloading.

Pull-down upright sliding door, easy to open and close; ensures a larger basket opening, saves space,and has a more compact structure Large-flow…

Products Description

More features of the dryer:

● Touch screen operation panel.

● Store up to 999 programs.

● Temperature difference “power cut-off”.

● Freely select able cooling temperature and time.

● Anti-wrinkle function.

● Manually start cylinder reversal for easy unloading.

● Large basket opening, more ergonomic, convenient loading and unloading.

● Pull-down upright sliding door, easy to open and close; ensures a larger basket opening, saves space,and has a more compact structure Large-flow, high-efficiency, easy-to-clean lint filter installed on the front side of the dryer for easy operation and maintenancee.

● Durable gearbox with direct drive.

● Fresh air is introduced to cool the cothes in the drum through an independent bypass cooling circuit,which ensures that the air does not come into contactwith the dryer’s heating device, which helps to shorten the cooling time of the linen. The bypass circuit also prevents the heating device from cooling down,reducing heat energy loss; it can quickly heat up whenit is started again, improving work efficiency.

DH High efficiency dryer technical parameters:

| Item | Unit | DH40S | DH55S | DH80S | DH100S |

| General information | |||||

| Max evaporation effiency00 | l/min | 1.3 | 1.7 | 2.8 | 3.5 |

| Qevaporation effiencyo) | l/min | 1.1 | 1.4 | 2.3 | 2.9 |

| Nominal flling quantity (at1:25 kg/)02 | kg | 40 | 55 | 80 | 100 |

| Electrical connection | |||||

| Connected voltage [UA] | V | 3×380 | 3×380 | 3×380 | 3×380 |

| Mains frequency | Hz | 50 | 50 | 50 | 50 |

| Connection value [S] | kVA | 8 | 9.5 | 15.5 | 17 |

| Current consumption [A] | A | 12 | 14.5 | 20 | 25.5 |

| Peak current [ls] | A/15s | 50 | 50 | 50 | 50 |

| Leakage current [ | Ma | 0/25 | 0/25 | 0/25 | 0/25 |

| cOS φ | ~0.9 | ~0.9 | ~0.9 | ~0.9 | |

| Terminal size | mm2 | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-10 |

| Rated capacity,ventilator | kW | 3 | 4 | 7.5 | 7.5 |

| Compressed air connection | |||||

| Connection | mm | 8 | 8 | 8 | 8 |

| Operatingpressure | bar | 6.5 | 6.5 | 6.5 | 6.5 |

| Compressed air consumption⁰4 | Nl/h | 14 | 14 | 14 | 14 |

| Additional compressed ai consumptionfortiltunloading(04 | Nl/h | 105 | 105 | 105 | 105 |

| Additionalcompressed air consumption for IR sensor 00 | NI/h | 180 | 180 | 180 | 180 |

| Steam connection | |||||

| Connection | DN25 | DN25 | DN25 | DN25 | |

| Operating pressure | bar | <12 | <12 | <12 | <12 |

| Steam consumption05 | kg/h | 145 | 190 | 225 | 265 |

| Max throughflow | kg/min | 3.6 | 4.7 | 5.5 | 6.5 |

| Condensate | |||||

| Connection | DN25 | DN25 | DN25 | DN25 | |

| Max.temperature | ℃ | 160 | 160 | 160 | 160 |

| Max back pressure | bar | 5 | 5 | 5 | 5 |

| Max.throughflow | kg/min | 3.6 | 4.7 | 5.5 | 6.5 |

| Exhaust air | |||||

| Connection | mm | φ300 | φ300 | φ350 | φ350 |

| Exhaust air volume flow 105) | m³/h | 17005300 | 20006000 | 23008000 | 28008500 |

| Item | Unit | DH40S | DH55S | DH80S | DH100S |

| Max.back pressure | Pa | 200 | 200 | 200 | 200 |

| Dimensions | |||||

| Machine dimensions(W×H×D) | mm | 1465×2289×1845 | 1465×2289×2130 | 1825×2650×2106 | 1825×2650×2336 |

| Transport dimensions(W×H×D) | mm | 1465×2289×1756 | 1465×2289×2068 | 1825×2650×2106 | 1825×2650×2336 |

| Infeed opening(W×H) | mm | 1660×2450 | 1660×2450 | 2020×2800 | 2020×2800 |

| Drum | |||||

| Diameter | mm | 1300 | 1300 | 1650 | 1650 |

| Depth | mm | 755 | 1040 | 940 | 1170 |

| Volume | 1002 | 1380 | 2010 | 2502 | |

| Weights | |||||

| Transport weight | kg | 1520 | 1580 | 1800 | 1880 |

| Operating weight | kg | 1520 | 1580 | 1800 | 1880 |

| Foundation loads | |||||

| Static point load at the floor | N/mm2 | 0.74 | 0.74 | 0.9 | 0.9 |

| Dynamic point load | kN | 0.2 | 0.2 | 0.42 | 0.42 |

| Excitation frequency of the dynamic point load | Hz | 0.6 | 0.6 | 0.55 | 0.55 |

| Number of feet | [pcs.] | 4 | 4 | 4 | 4 |

| Surface of the individual foot | mm2 | 5025 | 5025 | 5025 | 5025 |

| Miscellaneous | |||||

| Noise emission-Workplace-specific emission value | dB(A) | 74 | 74 | 75 | 75 |

All consumption values in the above table are average values under standard condi-tions.Effective capacity depends on operating site conditions and type of clothing.Depending on the processing method, these values can fluctuate significantly.

(01) Evaporation capacity in the main drying phase, nominal load 40/55/80/100 kg.volume ratio 1:25 kg/l, terry cloth material up to 365 q/m2, steam pressure 10 bar.(02) The optimal load depends on the volume of the items to be treated and thetype of clothing.(03)Three-phase five-wire system: L1/L2/L3/N/PE(04)Compressed air consumption refers to data at 20°C and (1000 hPa) ambientpressure conditions.

(05)Refer to the average value of 2.8 times/h.(06)Minimum value: exhaust volume during operation. Maximum value: exhaustvolume during the cooling phase.

The relevant parameters are subject to change without prior notice.Jinan Geyin Machinery Equipment Co., Ltd. reserves the right to modify technicalparameters according to technical improvements. Please contact our company forrelevant information.